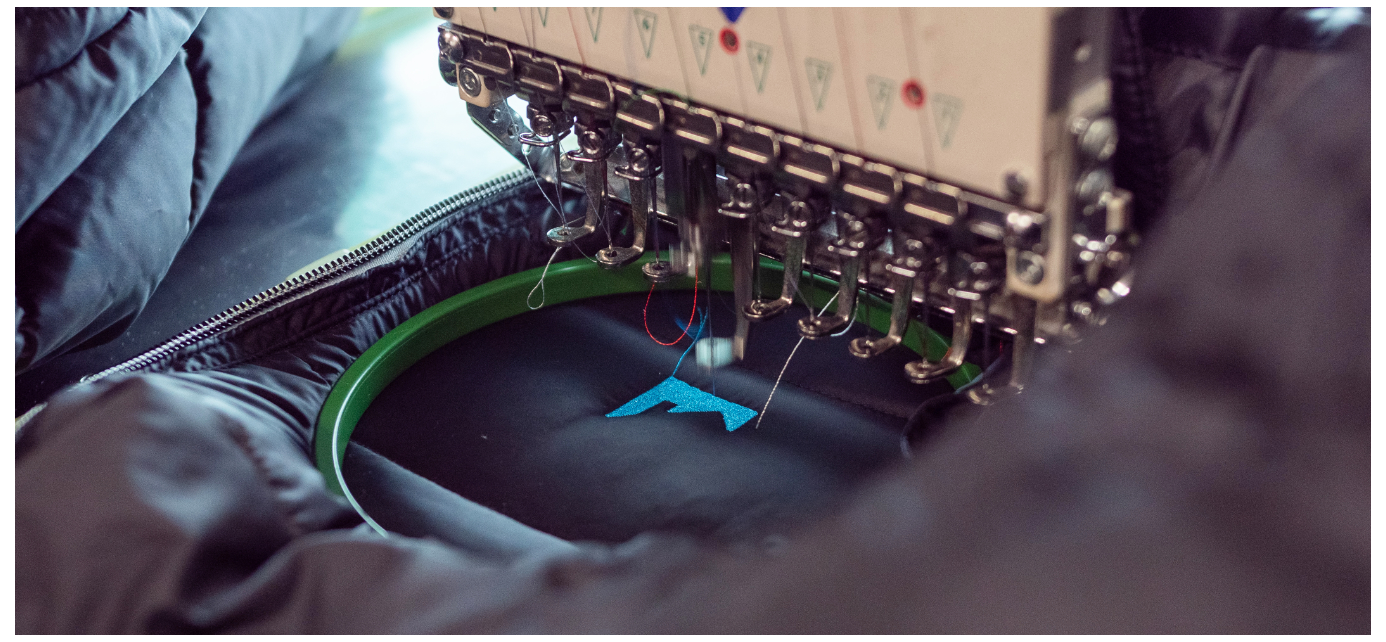

Computerised embroidery in promotional clothing

Haft komputerowy od kilku lat jest jedną z najpopularniejszych metod znakowania odzieży reklamowej i roboczej. Ies Polska, jako dystrybutor marek Fruit of the Loom, Russell, Result, Spiro i Jadea dostarcza szeroką ofertę koszulek polo, bluz, kurtek czy koszul do znakowania. W poniższym poradniku wyjaśniamy, jak działa haft komputerowy, jakie nici i stabilizatory wybrać, jak przygotować projekt oraz jakie ubrania dla pracowników z logo najlepiej się do tego nadają.

What is computerised embroidery?

The mechanism of computerised embroidery consists in transferring a design from a graphics program onto the fabric using a specialised, computer-controlled embroidery machine. Before production starts, the artwork is converted into a digital embroidery file, defining the stitch sequence, thread colours and their density. Next, the operator fastens the fabric in the hoop and places the appropriate stabiliser (backing) underneath. The embroidery machine, equipped with several needles, sequentially stitches the individual colours and layers of the embroidery – it can reproduce even complex motifs and shading and is highly repeatable.

Najpopularniejszym wariantem jest haft płaski, w którym wzór leży bezpośrednio na tkaninie. Dla mocniejszego efektu stosuje się również haft 3D (wykonywany na piance zwiększającej wypukłość) lub haft chenille (pętelkowy, kojarzony z puszystymi naszywkami szkolnymi). Zaletą tej techniki jest trwałość – ścieg nie ściera się jak nadruk, wytrzymuje pranie w wysokich temperaturach i nadaje ubraniom premium charakter . Dlatego haft sprawdza się w przypadku odzieży firmowej, odzieży BHP, uniformów gastronomicznych czy odzieży eventowej.

Equipment and accessories

Hoops – rings in various diameters that keep the fabric under tension. Well-tensioned fabric prevents the embroidery from puckering.

Threads – top and bobbin. The bobbin thread is thinner and most often white or black; the top thread is responsible for the colour of the design.

Needles – embroidery machines use special embroidery needles; thicker or metallic threads require needles with a larger eye.

Stabilisers (backings) – placed under and over the fabric, they increase the stiffness of the material, prevent puckering and protect the machine from thread breakage. We describe the types of backings in the next section. This small but essential equipment makes it possible to achieve neat, durable embroidery.

Embroidery threads – how to choose them?

The variety of threads available on the market makes it possible to match them to the properties of the fabric and the visual effect. It is worth knowing their characteristics to ensure a perfect combination with corporate or promotional garments.

Standard threads

Polyester – the most universal and durable material. Polyester threads are resistant to abrasion, chlorine, UV radiation and high temperatures, which makes them suitable for workwear and PPE. Thanks to their high strength, they are ideal for sportswear, towels and industrial fabrics.

Cotton – natural threads with a matte appearance. They give the effect of hand embroidery and are resistant to ironing at high temperatures, but they are less durable than polyester. They are used for elegant corporate clothing and natural fabrics.

Viscose – has a delicate sheen and creates flat, soft embroideries. It is lighter and less durable than polyester, so it works well in products that require delicacy (corporate clothing, shirts).

Acrylic – acrylic threads with a yarn-like coating are thicker and give embroidery a folk character. They are suitable for decorative motifs, especially on caps or thick sweaters.

Specialist threads

Metallic – made of a polyester core wrapped with a metallic film. They give a metallic effect (gold, silver, copper) and are used for crests, premium logos and liturgical elements.

Fluorescent – charged with light energy, they glow in the dark; used in eventwear or children’s gadgets.

Reflective – reflect light, increasing the visibility of garments on the road; used in vests, work jackets or clothing for cyclists.

Flame-retardant – made of aramid, resistant to high temperatures and sparks, so they are suitable for garments for firefighters and welders.

In addition to the type, the thickness of the thread is important. Fine threads (e.g. 40 wt) make it possible to achieve small details, while thicker ones (30 wt, 12 wt) increase the relief of the embroidery. Matching the thread to the fabric and design is crucial for durability and appearance.

Backings and stabilisers

A stabiliser is a layer of paper-like non-woven (backing) made of cellulose and synthetic fibres, which stiffens the fabric during embroidery. Proper selection of the backing prevents stitch distortion and protects the machines. The most commonly used are:

Standard backing (tear-away) – a structural non-woven that stabilises the fabric in all directions. After the embroidery is finished, the excess backing is torn away, leaving only a minimal remnant. It is suitable for thick, rigid fabrics such as sweatshirts for embroidery or premium T-shirts.

Fabric-type backing (cut-away) – made mainly of synthetic fibres. It is cut with scissors and therefore remains under the embroidery, which increases its stability on stretchy fabrics (T-shirts, polo shirts).

Water-soluble backing – dissolves in water after washing without leaving traces. It is used for lace-like embroideries, on towels and delicate fabrics, where tearing could damage the material.

Self-adhesive backing – with an adhesive layer that allows the fabric to be stuck down instead of clamping it in the hoop. It is suitable for small pieces or stretchy knits.

Experts recommend using only dedicated embroidery backings – using ordinary tailoring interlining or paper may damage the machine and worsen the appearance of the embroidery.

Preparing the design and best practices

Designing the motif – a correct design is half the battle

Key rules

Simple typography – small letters should be at least 5–6 mm high to remain legible and not merge with each other. Fonts that are too elaborate or have very fine lines lead to fraying of the thread.

Limited detail – computerised embroidery does not handle gradients and heavy shading well. A good solution is to simplify the logo into clear colour blocks.

Correct formats – files should be prepared in a vector or embroidery format (e.g. DST, PES), keeping the correct size. The artwork needs to be converted into stitches in dedicated software.

Size – a standard left-chest embroidery is 8–10 cm wide, while a large logo on the back corresponds to A4 format. The maximum size depends on the largest hoop (usually approx. 28 cm in diameter).

Fabric and stabiliser

The choice of thread and backing should depend on the fabric:

On thick, rigid fabrics (sweatshirt, heavy T-shirt), a tear-away backing is sufficient.

On elastic and thinner knits (garments for decoration, polo shirts for computerised embroidery), a cut-away or self-adhesive backing is recommended to keep the stitch in place.

For delicate fabrics (silk, lace), a water-soluble stabiliser is used to avoid damaging the fabric when tearing.

Most common mistakes and how to avoid them

Industry publications highlight several typical mistakes in embroidery:

Incorrect choice of font – letters that are too small or a very fine typeface make the embroidery illegible.

Overloaded design – too many details and colours make conversion to stitches difficult, causing the fabric to pucker.

Wrong stabiliser – thin fabrics require a denser backing, while on towels it is worth adding a water-soluble film (hydrofoil) on top so the stitches do not sink into the loops.

Incorrect hoop tension – fabric that is hooped too loosely may cause the embroidery to ripple; tension that is too tight deforms the garment.

No testing – before mass production, it is worth making a test embroidery on a similar fabric to assess the appearance and adjust the settings.

Following these rules will let you enjoy the result, which is a well-executed embroidery on clothing.

Overview of Fruit of the Loom and Russell products

Ies Polska offers an extensive range of promotional, corporate and workwear garments suitable for embroidery. Below we present the most popular models, their parameters and recommended branding positions.

Fruit of the Loom

Polo 65/35 (634020)

A classic item of corporate clothing designed for professional decoration. The 65/35 Polo Shirt is a blend of 65% polyester and 35% cotton, developed for wearing durability and stability during the decoration process. Polyester fibres provide shape retention and minimise shrinkage, while cotton guarantees wearing comfort and natural breathability.

The piqué structure with a weight of 180 g/m² creates an ideal surface for computerised embroidery – dense enough so that the embroidery does not show through to the other side, yet elastic enough for the needle to penetrate the fabric freely. The characteristic piqué texture helps to mask minor imperfections of the embroidery stabiliser. The reinforced placket with three tone-on-tone buttons provides a stable base for embroidery at chest height, where corporate logos are most often placed.

Key benefits for embroidery:

Dimensional stability thanks to polyester content – no distortion when tightening in the hoop

Universal 180 g/m² weight preventing puckering with dense embroideries

Side seams ensuring a good fit to the body

Availability in 20 colours allowing perfect matching of embroidery colours

Premium Polo (632180)

Premium Polo represents the highest quality in the Fruit of the Loom portfolio, offering an outstanding surface for high-end embroidery designs. Made from 100% combed ring-spun cotton, the shirt features a uniform structure that allows even the most detailed and refined embroideries to be executed.

The 180 g/m² weight combined with the piqué knit creates a stable base that does not collapse under the weight of large corporate embroideries. The combing process removes short fibres, leaving only long, strong yarns that do not pill around the embroidery even after many washes. Enzyme washing gives the fabric a softness that ensures even large back embroideries do not cause discomfort when worn.

Key benefits for embroidery:

Smooth combed cotton surface that showcases embroidery details

Pre-shrunk fabric reducing the risk of embroidery distortion after the first wash

Reinforced shoulder seams keeping embroidery in place on the sleeves

Three-layer placket resistant to deformation when embroidering near the collar

Premium fabric that enhances the prestige of the embroidered logo

Bluza Premium Set-In Sweat (621540)

Premium Sweat is a high-quality crew neck sweatshirt that we recommend for a wide range of embroidery projects. The composition of 70% combed ring-spun cotton and 30% polyester combines the best properties of both fibres – the natural softness of cotton with the stability of polyester during the embroidery process.

The universal 280 g/m² weight ensures that the sweatshirt copes well with large and heavy embroideries without pulling or puckering the fabric. The inside is softly brushed, which not only increases thermal comfort but also provides an additional stabilising layer for the embroidery. The set-in sleeve construction with double stitching guarantees that embroidery placed on the shoulders or upper back will keep its position throughout years of intensive use.

Key benefits for embroidery:

Universal, stable and smooth 280 g/m² surface ideal for large corporate embroideries

Flat seams minimising the risk of embroidery shifting

Herringbone back neck tape – an excellent, unique spot for personalisation embroidery

Wide range of 9 colours enabling creative combinations with embroidery colours

Rusell

Stretch Polo (566M)

A bestselling hooded sweatshirt created for branding in the world of corporate clothing, combining everyday style with the professionalism required in company apparel. The classic composition of 80% combed ring-spun cotton and 20% polyester with a weight of 280 g/m² provides an optimal surface for embroidery designs.

The kangaroo pocket has been reinforced with double stitching, which allows embroidery on the top edge without the risk of distortion. Even with large embroideries, wearing comfort remains high, and the large, smooth surface makes it possible to create even the most sophisticated designs and patterns.

Key benefits for embroidery:

Thick, 3-layer fabric – the material does not ripple under dense embroidery

Stable cut and strong seams – the logo does not pull the sweatshirt out of shape and holds the line

Rib cuffs with elastane, ideal for subtle personalisation embroidery

Double stitching in strategic areas stabilising large embroideries

Authentic Hooded Sweat (265M)

A bestselling hooded sweatshirt created for branding in the world of corporate clothing, combining everyday style with the professionalism required in company apparel. The classic composition of 80% combed ring-spun cotton and 20% polyester with a weight of 280 g/m² provides an optimal surface for embroidery designs.

The kangaroo pocket has been reinforced with double stitching, which allows embroidery on the top edge without the risk of distortion. Even with large embroideries, wearing comfort remains high, and the large, smooth surface makes it possible to create even the most sophisticated designs and patterns.

Key benefits for embroidery:

Thick, 3-layer fabric – the material does not ripple under dense embroidery

Stable cut and strong seams – the logo does not pull the sweatshirt out of shape and holds the line

Rib cuffs with elastane, ideal for subtle personalisation embroidery

Double stitching in strategic areas stabilising large embroideries

Męska koszula z długim rękawem Oxford (932M)

The R932M Russell Collection Long Sleeve Easy Care Oxford Shirt is a classic piece of corporate clothing, designed as an elegant backdrop for an embroidered logo. The blend of 70% cotton and 30% polyester in an Oxford weave combines the natural look and comfort of cotton with the durability and easy-care properties of polyester – the shirt withstands frequent washing and ironing well, retaining its shape and a stable embroidery position.

The 130 g/m² (white) / 135 g/m² (colours) weight provides the fabric with sufficient density so that the embroidery does not show through, while it remains light enough for the needle to penetrate the fabric freely without excessively stiffening the entire front. The subtle texture of the Oxford weave discreetly masks the edges of the backing and minor imperfections of the stabiliser. The classic cut, yoke with two pleats at the back, left chest pocket, reinforced button placket and rounded hem create a stable, predictable base for standard corporate logo placements.

Key benefits for embroidery:

Dimensional stability of the 70/30 blend – the shirt does not deform when tightened in the hoop and retains its shape after many washes

130–135 g/m² Oxford weave – the fabric does not crease excessively under dense embroidery

Yoke with two pleats at the back – the shirt “moves” with the shoulders, so chest embroidery is less strained and does not crack

Left chest pocket and reinforced placket – provide a natural, stable point for a classic corporate logo

Easy-care properties – fewer creases after washing mean less ironing around the embroidery

Special tips for embroiderers: For the R932M shirt, light tear-away or cut-away stabilisers (approx. 30–40 g/m²) work best; for very small logos, you can additionally use a thin water-soluble stabiliser as an auxiliary top layer. Standard embroidery threads in thickness 40 are recommended. Ideal embroidery locations are the left chest (above the pocket or instead of it), cuffs and collar. Due to the nature of the Oxford fabric, it is worth avoiding excessive stitch density and not going below 5–6 mm in letter height to maintain an elegant, legible effect.

Industries and applications of computerised embroidery

Computerised embroidery is used in many sectors of the economy. Below are examples of industries where corporate clothing with embroidery is worth considering:

Gastronomy and hospitality – white shirts, 65/35 polos and aprons with embroidered restaurant logos underline a professional image. Resistance to frequent washing makes embroidery ideal for hotels and catering.

Logistics and retail – Super Premium T T-shirts and Authentic Sweat sweatshirts with the company name increase staff recognition in warehouses and shops. Embroidery does not chip off during handling of goods.

Manufacturing and construction – durable workwear with embroidery (100% cotton T-shirts, fleeces, softshell jackets) meets PPE clothing requirements and helps identify teams on construction sites.

Events, promotion and marketing – event clothing with a logo (sweatshirts, T-shirts, softshells) is widely used at trade shows, conferences and concerts. Embroidery gives a prestigious look and does not crack like a print.

Music merch and online sales – embroidered caps, hoodies and T-shirts with unique motifs are valued by fans for their durability and high quality of workmanship.

Materials to avoid

Although computerised embroidery is versatile, not every fabric is suitable for this technique. Avoid:

Very thin and elastic fabrics – delicate knits (e.g. silk, fine jerseys) may pucker or let threads show through, and dense embroidery deforms them.

Highly stretchy materials (lycra, stretch) – the needle may cause ladders and stretching. For such fabrics, transfer printing is recommended.

Slippery or coated fabrics – satin, nylon or water-repellent coatings may be damaged by needle punctures; large embroideries weaken the waterproof properties of softshells. It is better to stick to small elements here.

By following these rules, you increase the aesthetics and durability of the finished products.

Embroidery placement, aesthetics and durability

The decision where to place the embroidery affects wearing comfort, logo visibility and garment durability. According to industry practice:

Left chest (heart area) – the most popular location, accounting for approx. 90% of orders. The logo is visible during conversation and does not interfere with the garment’s cut.

Sleeves – additional elements (flags, slogan, website address) most often placed on the right sleeve. They are well exposed when shaking hands.

Back – a large logo or slogan on the back (e.g. A4 size). Works well for events and PPE clothing, but requires a large hoop.

Collar and hood – discreet embroidery of the company name or initials on the shirt collar, hoodie or the edge of a cap.

It is important to keep the right proportions: embroidery that is too large may “stand stiff” on the fabric, while embroidery that is too small will be illegible. The lining layer should also be taken into account – on sweatshirts and quilted jackets it is worth opening the seam (decoration access) and then carefully sewing the lining back to hide the bobbin threads.

FAQ – frequently asked questions

1. Is embroidery more durable than print?

Yes. The stitch penetrates the fabric and does not wear off like many prints. An embroidered logo can be ironed and washed at higher temperatures without the risk of the print layer cracking or colours fading rapidly – provided the care instructions on the manufacturer’s label are followed.

2. Are embroidered garments waterproof?

The thread itself does not provide waterproofness. On softshells and rain jackets, embroidery can create micro-holes in the outer layer, locally reducing water resistance. Therefore, on technical garments, it is advisable to use rather smaller embroidered logos or transfer prints, especially in critical areas.

3. How do I care for embroidered clothing?

Wash garments inside out, avoid aggressive bleaches and strong stain removers, and iron on the reverse side or through a thin cloth.

For polyester/cotton fabrics, washing at 40°C is generally recommended, unless the label allows more. Russell polo shirts, such as the Ultimate Polo R577 and Hardwearing R599, as well as the Fruit of the Loom 65/35 Polo, can be washed at 60°C (without print, in line with the manufacturer’s instructions).

4. What is the maximum size of an embroidery?

The practical limitation is the hoop size and the area available in the machine. Large standard hoops for garments are usually approx. 25–28 cm in diameter, which allows for large motifs on the back or front of a sweatshirt.

For chest logos, a typical, safe width is around 8–10 cm – this way the mark is clearly legible and proportional to the garment.

5. Which products are best for embroidery?

Garments with higher weight, a dense weave and a stable composition work best:

R932M polo shirts

Authentic Sweat sweatshirts

Softshells with decoration access (opening panels)

Thin and very stretchy materials (e.g. lightweight technical sports T-shirts) are usually better decorated with print.

6. How many colours can an embroidery have?

Modern embroidery machines usually have a dozen or so needles, which allows the use of several to a dozen thread colours in one design without changing spools. However, it is worth remembering that the more colour changes, the longer the embroidery time and the higher the production cost.

7. What should I choose – embroidery or print?

Embroidery is ideal for small and medium-sized logos, initials, patches, workwear and premium corporate clothing. It provides an elegant, three-dimensional effect and very high durability.

Print (e.g. screen printing, transfer printing) is better suited for large motifs, graphics with tonal gradients, and thinner, more elastic fabrics.

Summary

Computerised embroidery is a beautiful, elegant and durable decoration technique that increases the value of promotional and corporate clothing. With proper design preparation, correct choice of threads and stabiliser, and suitable garments – such as R932M polo shirts, Authentic Sweat sweatshirts, Premium Set-In Sweat from Fruit of the Loom or Russell shirts and jackets – you can achieve outstanding aesthetic results. In various industries – from gastronomy, through logistics and construction, to events and music merch – embroidery helps brands stand out and supports a professional image for employees. By keeping in mind the limitations of certain fabrics and choosing the right embroidery placement, you gain durable staff garments with logos that will serve for years.

Ies Polska is a distributor of promotional clothing, branded corporate wear and logo apparel, operating exclusively in a B2B model. Our company is the largest official Fruit of the Loom and Russell partner in Poland, and our range also includes, among others, Result, Spiro and Jadea. Thanks to direct relationships with manufacturers, we ensure stable availability of collections and reliable sourcing of promotional, corporate and workwear garments.

The extensive assortment includes T-shirts, polo shirts, sweatshirts, softshells, jackets, fleeces, caps as well as workwear and safety workwear – from basic models to premium lines for demanding projects. A warehouse covering several thousand square metres and stock counted in millions of pieces make it possible to handle both small orders and large projects involving protective clothing, workwear for technical teams or complete corporate uniforms.

Ies Polska’s customers are mainly embroidery shops, print shops, advertising agencies, online stores and companies building their own collections of corporate and workwear garments. Partners receive not only access to products, but also support in selecting styles for specific decoration techniques such as computerised embroidery, transfer printing, screen printing or DTG. Thanks to this, for many companies Ies Polska is not only a supplier of promotional, safety and corporate clothing, but a long-term partner in building a consistent brand image on apparel.

iespolska.eu

Cookies

Cookies